OPIX Systems, LLC

Master Systems Integrators

OPIX Systems, LLC

Master Systems Integrators

Building Management Simplified

About Us

Our Mission

OPIX stands for Open & Proprietary Information Exchange. Our mission is to simplify building management systems. We seek to empower our customers with intuitive and easy to learn tools.

Read More

About US

Company Profile

OPIX Systems was founded in 2017 by Managing Partners Jim Leaper and Charlie Garcia, following Josh Bedenbaugh in 2021. Since that time OPIX has grown at an exceptional rate.

Read More

Automation

Systems Integration

Integrate any system into a simple, easy to monitor and schedule dashboard. If you can dream it, we can find a way to integrate it into your building automation system.

Integration

Lighting Services

Design & Upgrades

OPIX has the technical and aesthetic training to help you implement a lighting solution that creates the best environment for your facilities needs while also saving energy.

Intelligent Lighting

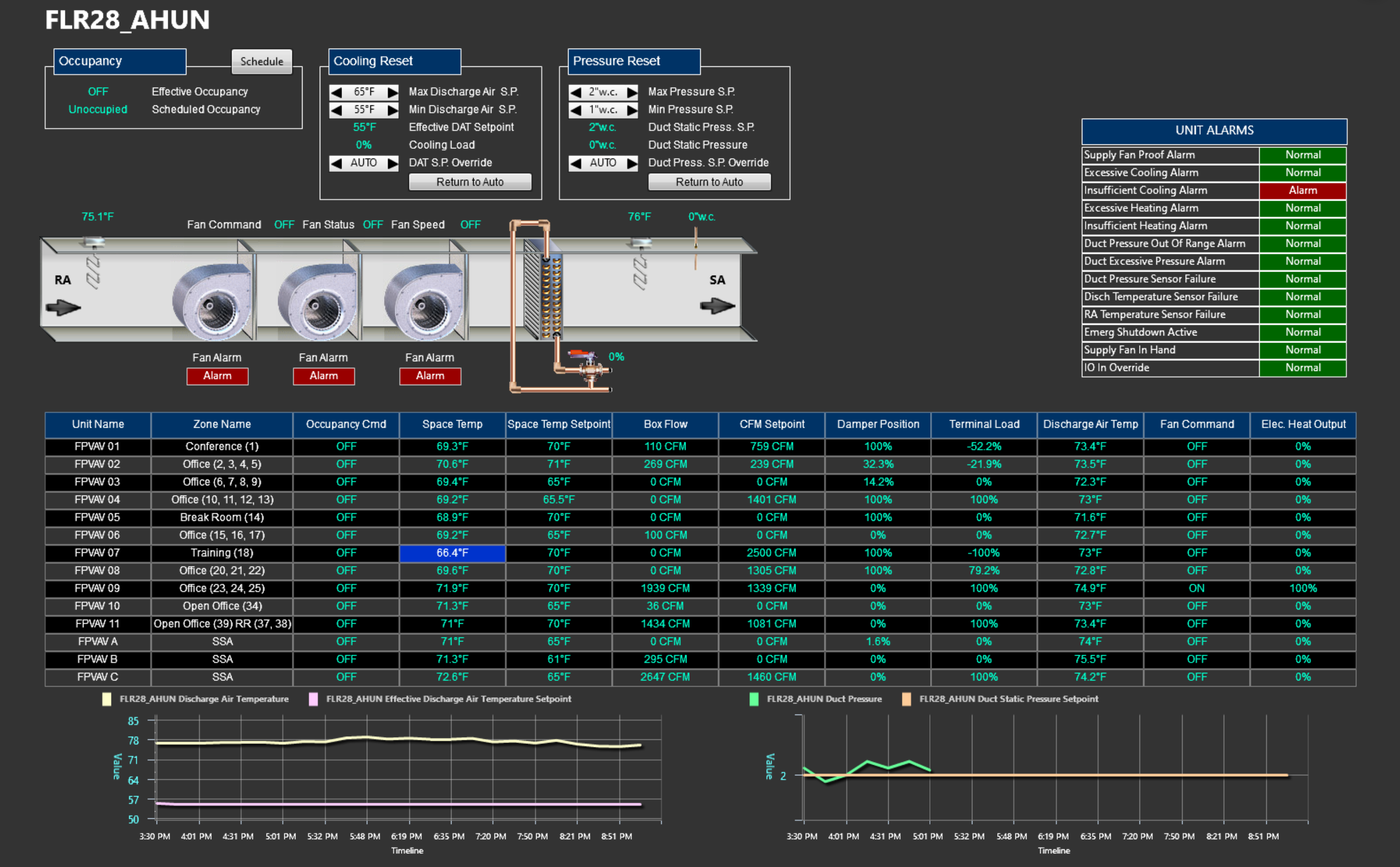

Graphics